Production Information

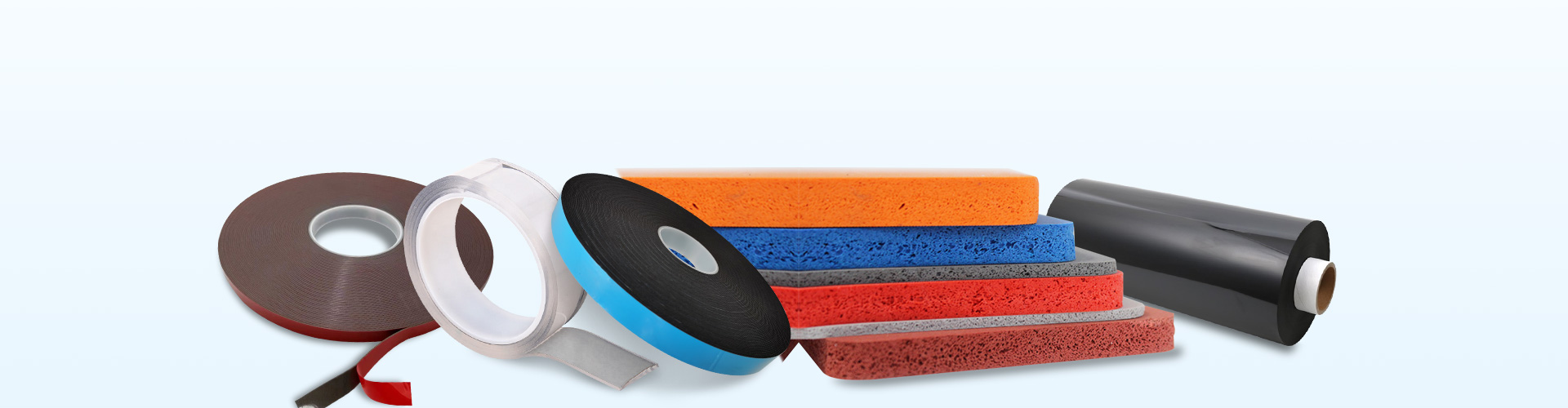

- EVA strong adhesive foam tape is made of imported glue and foam with good toughness. It can be pasted on both sides.EVA rubber and plastic products are new environmentally friendly plastic packaging materials, which have the advantages of good cushioning, shock resistance, heat insulation, moisture resistance, chemical corrosion resistance, etc., and are non-toxic and non-absorbent. EVA rubber and plastic products are designed to be processed and formed. Their shockproof performance is better than that of traditional packaging materials such as polystyrene (foam), and they meet environmental protection requirements. They are the best choice for export products. Compared with shock-proof packaging, it can be cut and formed; due to the large difference in density, it can also have a wider range of uses.

Product Description

- Features of EVA Foam Tape:

Water resistance: closed cell structure, non-absorbent, moisture-proof, good water resistance.

Corrosion resistance: resistant to chemical corrosion such as seawater, oil, acid, alkali, etc., antibacterial, non-toxic, odorless, and non-polluting.

Processability: no joints, and easy to process such as hot pressing, cutting, gluing, laminating, etc.

Anti-vibration: high resilience and tensile strength, strong toughness, and good anti-vibration/cushioning performance.

Thermal insulation: excellent thermal insulation, thermal insulation and cold protection and low temperature performance, can withstand severe cold and exposure.

Sound insulation: closed cells, good sound insulation.

Product Use

Physical Properties

| The following parameters are for reference only | |

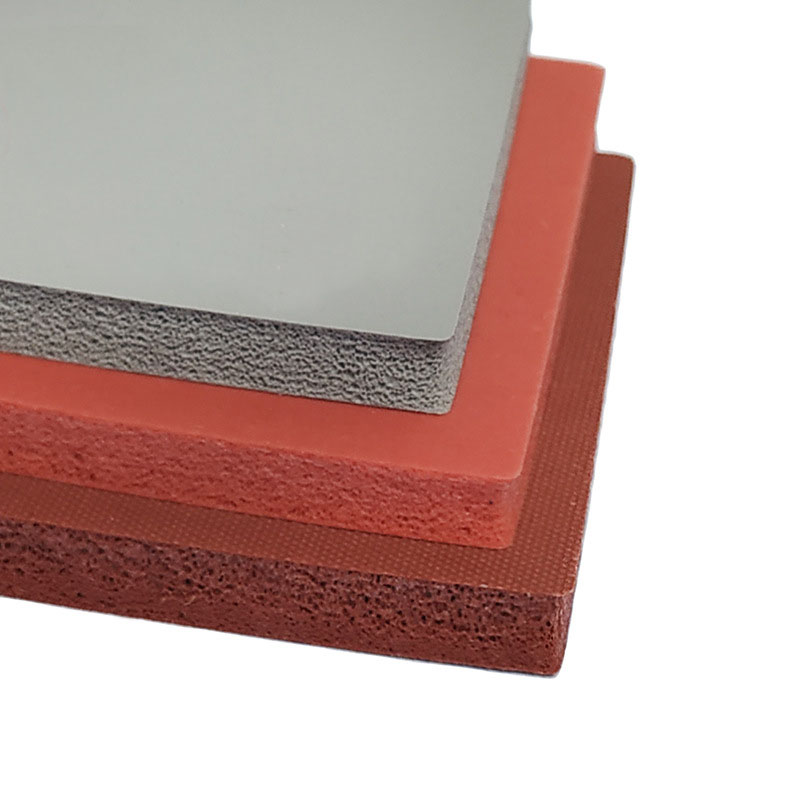

| Thickness | 0.3MM-6.0MM Or Customized |

| Width | 10-1040MM |

| Length | 15m-50m Or Customized |

| Color | White/Black Color Foam |

| Release liner | Paper/Film Liner |

| Backing | EVA Foam |

| Adhesive | Hotmelt Glue /Solvent Acrylic Glue |

| Hardness | 38 45 |

| Peel Adhension | 15N-20N/25MM |

| Holding power | >24h |

| Temperation resistance | -10℃-80℃ |